Variable Force Springs In New Point Of Purchase Display

source:Qianye Precision time:2022-9-14

Automatic advance shelves are more widely used in stores and people’s lives, and are more often used for displaying and placing goods (incense hata, rosemary, etc.). However, the conventional shelf propeller has one end of the baffle on both sides fixed and the other end movable. Although in use, after the first row of goods is taken away, the second row of goods will be automatically pushed to the first row, which can save the staff’s finishing time, but in the process of pushing the goods, it is easy to cause the goods in the back row to pop out of the display slot due to the activity of the ends of the shelf advancer on both sides of the stopper, which brings inconvenience to the use.

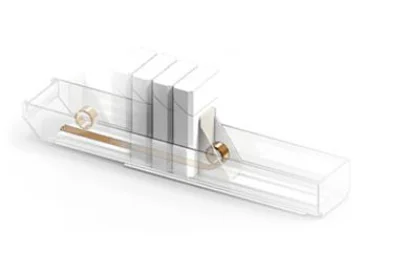

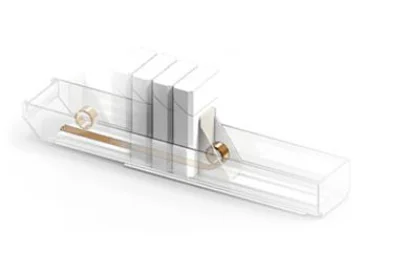

To provide a new type of shelf propeller for the problem of the shortcomings of the existing technology. The new shelf propeller includes a base plate, a side plate, a push plate and a baffle plate, the base plate, the side plate, the push plate and the baffle plate are enclosed to form a shelf slot for placing goods. The side plate is provided on both sides of the bottom plate, and the push plate is provided on the bottom plate, and a variable force spring is provided between the push plate and the bottom plate, and the variable force spring drives the push plate to move. The baffle plate is set at the end of the bottom plate. The utility model structure design is simple, reasonable, orderly, occupy little space, easy to take and put, the goods take automatic replenishment, not easy to scatter, neatly placed.

Variable force springs can break through the traditional clockwork influenced by Hooke’s law, so that the stroke and force are no longer increased in equal proportion, but can achieve a negative slope of the step type of constant force and other kinds of elasticity-displacement combinations, according to the needs of mechanical engineering, using the relationship between elasticity and displacement stroke, in a specific use of occasions, to do a variety of elasticity curve changes in the design.

Variable force springs are used in shelf pushers. When there are many items, a large force is needed to push the items forward smoothly. When the items gradually decrease, the force also needs to be reduced to avoid crushing the items with too much force.

Shenzhen Qianye Precision Metal Co., Ltd. was established in 2006 to supply high-quality stainless steel springs for many fields. Through continuous efforts

20 patent certificates and

4 spring equipment software copyrights have been granted by the State Intellectual Property Office, and an enviable industry influence has been built. The company designs and manufactures a wide range of

power springs, constant force springs, constant torsion springs, variable force springs and motor brush spring. Qianye works in close partnership with its customers in developing bespoke solutions to meet their individual needs. In order to offer better services, it has been continuously investing in production technology and supply chain. The company itself is a stainless steel raw material manufacturer. Because of the support of raw materials, it is not subject to material restrictions when making spring products; special material requirements can be developed and manufactured; furthermore, the delivery time is greatly shortened. Quality is of the utmost importance and Qianye are certified to ISO9001, ISO14001 and national high-tech enterprise with a big emphasis on the training of its employees. Its spirit is “treat people with sincerity and create things with sincerity” to ensure it strives for excellence.