إيجابياتنا

-

-

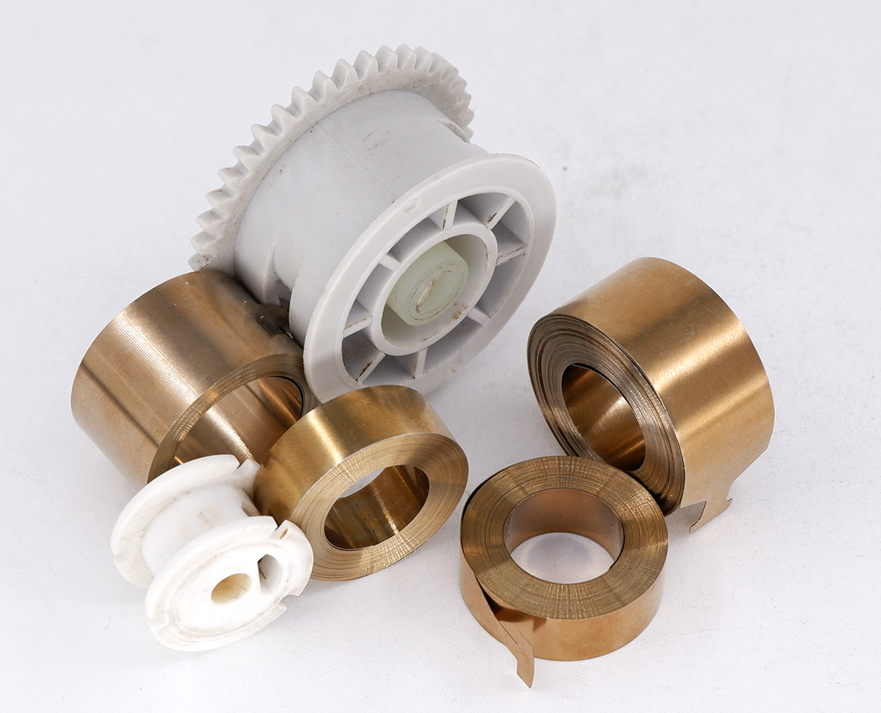

مواد أولية

● منتجات الزنبرك مصنوعة من مادة الفولاذ المقاوم للصدأ 301 الأكثر ثباتًا ؛

● التعاون العميق مع شركات المنبع في البحث والتطوير ، وبدء صهر خاص من القضبان ، وفهم أفضل لجودة المواد الخام ؛

● نحن لسنا مقيدين بالمواد ، على الرغم من أنه يمكن أيضًا تطوير وإنتاج متطلبات المواد الخاصة.

-

معدات الإنتاج

● مجهزة بجهازين خاصين للقطع (الحد الأدنى لعرض القطع 2 مم ، تحمل التقطيع ± 0.05 مم) ؛

● نحن نستخدم جهاز اختبار الصلابة الدقيق ، وآلة طحن الحواف ، وآلة لف الزنبرك ، وفرن درجة حرارة ثابتة للمعالجة الحرارية (炉) ، وكاشف خاص (检测 器) وسلسلة من خطوط الإنتاج المهنية ومعدات الاختبار ؛

● نحن متخصصون في البحث والتطوير المستقلون في الصين لمصنعي آلات اللف الزنبركي. تمت ترقيته من الجيل الأول إلى الجيل الثامن ، مما ضاعف من عمر الربيع.

● على سبيل المثال ، متوسط العمر السوقي لمقاود الكلاب يتراوح بين 2000 و 6000 مرة ، وتتراوح نتائج الاختبار لدينا بين 30000 و 100000 مرة.

-

-

-

عملية الإنتاج

● نحن متخصصون في إنتاج نوابض الفولاذ المقاوم للصدأ ذات القوة الثابتة وأي زنبرك متغير القوة ، بأعلى المعايير الدولية لتكنولوجيا الإنتاج.

● من قطع المواد الخام ، طحن الحواف ، لف الزنبرك ، القص ، معالجة الذيل والمعالجة الحرارية ، كلها تستخدم آلات صناعية أوتوماتيكية للإنتاج المستمر.

● حصلت الشركة على 12 براءة اختراع لنماذج المنفعة (实用 新型 专利) ؛ 1 براءة تصميم ؛ براءة اختراع معدات منصة اختبار كلال الربيع.

-

تكنولوجيا التصميم والتطبيق

● يمكننا تلبية جميع متطلبات التخصيص المعقولة. في الوقت نفسه ، لدينا تقنية قوية لمساعدة العملاء على تحسين وحل جميع مشاكل تطبيق الربيع.

● يمكننا القيام بالتصميم الهيكلي للعملاء ، المصمم خصيصًا لتعظيم وظيفة الزنبرك.

● لقد ساعدنا العديد من العملاء في حل مشاكل التطبيق العملية وضربنا قيمة منتجاتهم.

-